Six Sigma Breakthrough Strategy in Customer Satisfaction

Introduced in 1979 and popularised in 1987 by Motorola, Six Sigma is a groundbreaking strategy for drastically reducing defects in Motorola's manufactured electronics (Qureshi et al. 2012). Total quality management was the focus of the strategy. Quality is everything in today's business world. Paraphrasing Alex Trotman from Ford: We are in a new era of competition. In the future, total quality management (TQM) will be the new standard, not a one-off. Not everybody will be here in a few years. It is a battle for survival, and total quality will determine the winners and losers (Domingo, 1997). This has become more and more true as customers' knowledge and sophistication has grown as a whole.

Sigma is a measure of how far something differs from the mean. There is a range of three to six in the Sigma strategy, with the highest being 6. Since just a few 3.4 defective parts per million (PPM) characterise six sigma, businesses and firms are able to minimise mistakes in all operations to the point where they are nearly inconsequential.

Six Sigma places the customer at the heart of everything the company does. If a product or service fails to please the customer, it does not meet the definition of quality in this context; thus, it is not good enough. This approach retains customers. Customers are more likely to stick around when they know they're getting a good deal, which in turn increases shareholder value. In this way, companies would have had the best of both worlds.

Businesses may substantially improve their bottom line by structuring and monitoring their day-to-day company processes in a manner that minimises waste and ensures value for money for resources consumed while enhancing customer delight and satisfaction (Harry and Schroeder 1999).

An organised and methodical strategy for developing novel services and products as well as strategic process optimization that use statistical methodologies and the scientific method to achieve remarkable reductions in customer determined defect rates has been characterised as Six Sigma (Linderman et al, 2003).

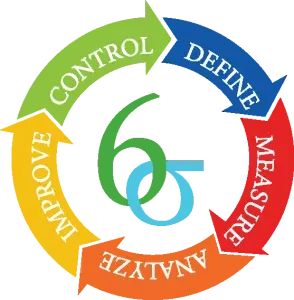

When used in conjunction with statistical tools and methodologies, Six Sigma is regarded a strong business approach that reduces process variability and waste inside corporate processes while also using a well-structured continuous improvement methodology (Qureshi et al. 2012).

These three definitions of Six Sigma all have one thing in common: they all emphasise the need of eliminating waste. In addition, Qureshi et al. say that Six Sigma is most often utilised for process improvement (2012).

Customers' satisfaction and shareholder value are the primary objectives of enterprises. It's not surprising that businesses are looking to significantly improve customer satisfaction and shareholder value in light of increased competition at both the international and local levels.

A company's most important goals are customer satisfaction and shareholder value. The reason for this is that businesses cannot survive without satisfied customers, and satisfied customers are the lifeblood of any business. A business must be able to generate a high enough profit to satisfy its shareholders' needs, which necessitates that the company be able to operate at its maximum efficiency.

Shareholders and customers alike desire better goods and better returns on their money. Consequently, the firm is under a lot of strain. Nothing but a "two birds with one stone" solution would do in this situation. This is where the Six Sigma methodology comes into play.

Six Sigma is the only quality model that actively pursues perfection, despite the fact that there are alternative techniques and models. As a strategy, Six Sigma is more than 3.4 failures per million opportunities per product or service transaction; it is a vision.

To some, the Six Sigma method may seem to be prohibitively costly due to its demand for perfection in all aspects of the firm (e.g. customers, processes, and personnel). Studies have shown, however, that using the Six Sigma strategy may lead to better product quality and reduced development costs across a wide range of industries (Harry and Schroeder 2000).

According to the above, higher quality goods result in a decrease in manufacturing costs. By decreasing variability, customer happiness and shareholder value are greatly enhanced. The Six Sigma strategy has helped major corporations like General Electric, Polaroid, Motorola, turn things around for the better (Hahn et al. 1999).

These are just a few of the numerous reasons why I believe Six Sigma is a game-changing strategy for increasing customer happiness and shareholder value across the board.

You

Might also Like:

References

Arthur, J., 2000. Six

Sigma Simplified-Quantum Improvement Made Easy. Denver, Lifestar.

Domingo, R. T., 1997.

Quality means survival-caveat vendidor let the seller beware. Singapore, New

York; Prentice Hall.

Hahn, G. J., Hill, W.

J., Hoerl, R. W., & Zinkgraf, S. A., 1999. The impact of Six Sigma

improvement—A glimpse into the future of statistics. American Statistician, 53 (3), pp. 208– 215.

Harry, M. and

Schroeder, R., 1999. Six Sigma: The Breakthrough Management Strategy

Revolutionizing the World’s Top Corporations. Doubleday: New York, 1999.

.webp)

No comments: